Damaged Cargo

Cargo damaged in transit

Key Points

There are certain key points that need to be kept in mind while making any type of cargo transportation to avoid cargo damage. At CEJIPAC, we take the following measures to ensure that the goods are transported safely and without any damage.

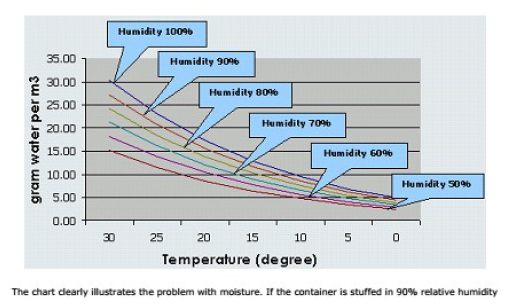

1. Sudden changes in temperature can lead to condensation, which can further cause water damage to the goods while transportation. Other than that the shifting of goods is also a major reason behind the damage caused to cargo.

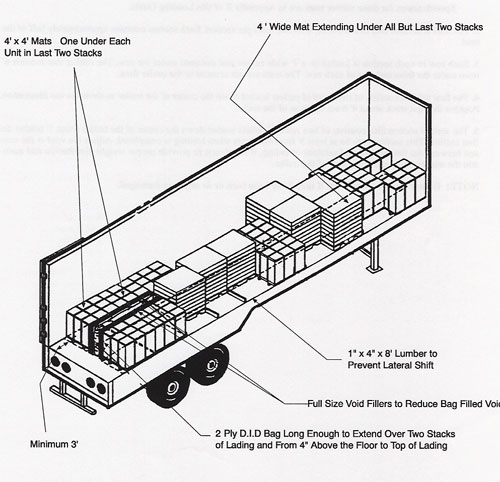

2. If there is any gap between the cargo loads and they are not tightly packed, it is obvious that the goods would shift while transportation. These small or minor gaps may lead to larger spaces which may cause the load to shift due to even a slight vibration and clash with each other or the walls leading to further breakage.

3. We categorize different types of cargo loads into harder loads, softer loads and fragile goods so that none of the goods get damaged due to any collision while transportation.

4. There is a strict need to load all the goods in the container uniformly so that the vessel does not tilt while transportation.

5. The cargo should be protected from any type of moisture present in the container. This moisture can be caused due to anything like the wooden floor, air moisture etc. Keep a check on this moisture as it may lead to further condensation due to climatic or temperature change and damage the cargo.

Some common hazards in transportation of goods

Accidental ImpactsDuring material handling operations , the goods can be damaged by accidental impacts. Goods normally go through many handling operations from the factory to the sales warehouse .Therefore there is always risk of accidental impact – knocking against each other, knocking against the container wall, pierced by the tines of the forklift or dropped from a height etc.

Compressive forces

Stacking in storage and transportation can exert excessive compressive forces onto the bottom layer of goods.This problem can be aggravated by vibration and compaction when the goods are being transported in a vessel , railcar or truck. CEJIPAC SDN. BHD.(364140-V) 157, Road 5, Minden Heights, 11700 Gelugor,Penang , Malaysia Tel/Fax:604-6580157 Website: /

Shock and vibration

When goods are handled and transported , they are subjected to shocks and vibration. Depending on the handling or transportation method, these can be quite severe. For example , the sea can be very rough when the vessel is sailing .A truck going through a mountain terrain will be subjected to tremendous shocks and vibration.

Extreme temperature and humidity in storage or transportation.

The weather can be unpredictable.Especially in the tropics , the temperature and humidity can be very high . This will promote bateria or mold infestation .Water condensation may also take place if there is a sudden drop in temperature due to rain or when the sun sets in the evening.

Creep

Goods are normally bundled by strapping , stretched wrapping or vacuum wrapping etc. There is a tendency for the strappings and wrappings to come loose due to the compressive and compacting forces at work during transportation .When this happens , the cargo can shift and knock against each other or against the walls of te container , truck or vessel.

The Hidden Cost Of Damaged Cargo

It is quite natural for manufacturers to allocate the major part of their resources to the manufacturing process to ensure their products meet the quality , cost and cycle time standards .The shipment of semifinished/finished goods is outside their area of focus . In most cases , they are only alerted when their customers complain of damaged goods .By then , they would have lost some goodwill with the customer concerned and will spare no effort to try to pacify the customer. In reality , there are many hidden cost associated with damaged cargo .Higher Cargo Insurance Premium

The insurance premium is proportional to the claim loss experience . Higher claims result in higher insurance costs.

Additional Freight Charges

In most cases , replacement goods may need to be sent by expedited freight so that the customer does not face any distruption in its operations. Expedited freight service( eg. courier service) is normally very expensive.

Additional Manufacturing Cost

The damaged goods need to be replaced .So, additional costs will be expended to produce the replacement goods.Can be costly for custom made products as it may entail changing equipment set up.

Lost Revenues

Obviously , the damaged goods cannot be sold and so will be deducted from the sales.

Costs Incurred In Additional Sales Calls

More time and effort will be expended to pacify the customer and coordinate the spurt of corrective and remedial activites by the different teams

Investigation Cost

This event will normally require a Corrective Action Report (CAR) .So , more time and effort will be expended to investigate the incident and implement the corrective actions recommended .

Brand Damage

This incident will also dent the brand name of the company . So , it would be prudent for the company to ensure ther is no more damaged cargo in future shipments.

Customer Dissatisfaction

There is a cost associated with customer dissatisfaction which we may not be able to quantify immediately .The customer may decide to place a higher proportion of their orders with other suppliers or in extreme cases, cancel their orders.

Loss of reputation

This incident cost loss of reputation by way of mouth( now, we have Twitter, Facebook,WeChatetc)Potential customers who hear of it may be put off.

Cost Incurred by Affected Customer

The affected customer may have incurred extra costs like cancelled sales, delayed fulfilment, additional clearance charges etc which they may want to claim from the manufacturer.

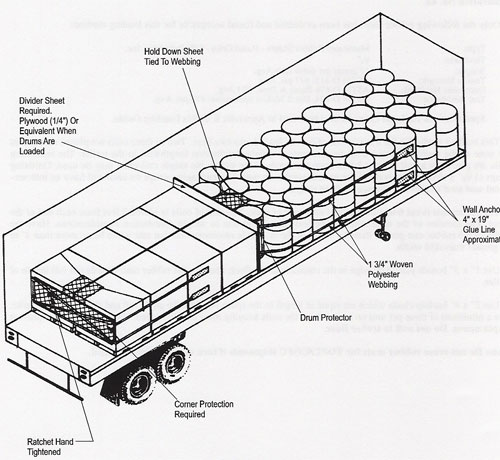

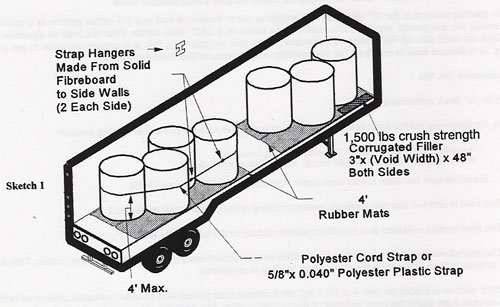

Cargo Load Securing For Containers

PurposeTo secure the cargo loads stowed in containers so that it is not damaged during transportation.

Applicable Specifications

- US Federal Motor Carrier Safety Administration(FMCSA), 49CFR Parts 392 & 393

- CTU ( cargo transport units) Packing Guidelines – International Maritime Organization (IMO) and Intern

- Intermodal Loading Guide – American Association of Railroad (AAR)

- European Railway Regulations (RIV)

Who is responsible?

- Shipper or

- The party responsible for loading the container

- Most liability conventions exonerate the carrier for damage caused by inadequate loading or securing

Definitions 1

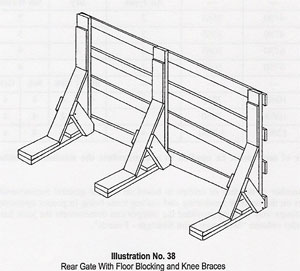

- Blocking

A structure , device or another substantial article placed against or around an article of cargo to prevent horizontal movement - Bracing

A structure , device or substantial article placed against or around an article of cargo to prevent it from tipping, that may also prevent it from shifting

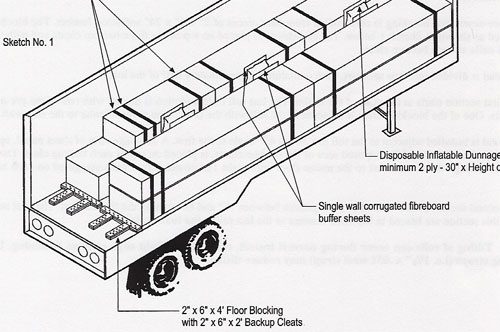

Definitions 2

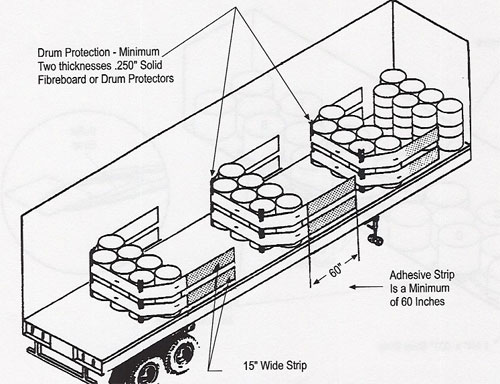

- Dunnage

All loose materials used to support and protect cargo - Dunnage Bag

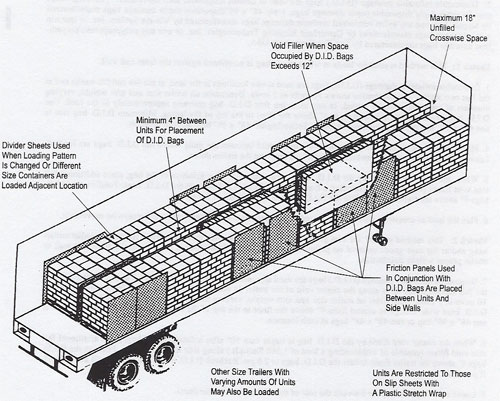

An inflatable bag intended to fill otherwise empty space between articles of cargo or between articles of cargo and the walls - Void filler

Material used to fill a space between articles of cargo and the structure of the container and have sufficient strength to prevent movement of the articles of cargo

Definitions 3

- Tiedowns

A combination of securing devices which forms an assembly that attaches articles of cargo to , or restrains articles of cargo in a container and is attached to anchor points - Working Load Limit(WLL) The maximum load that may be applied to a component of a cargo securing system during normal service, usually assigned by the manufacturer of the component.

-

Aggregate Working Load Limit

Summation of the working load limits or restraining capacity of all devices used to secure an article of cargo

Forces for road transportation

The FMCSA requires cargo securing systems capable of withstanding the following 3 forces applied separately:

- 0.8g deceleration in the forward direction

- 0.5g acceleration in the rearward direction

- 0.5g acceleration in a lateral direction

General cargo securing rules

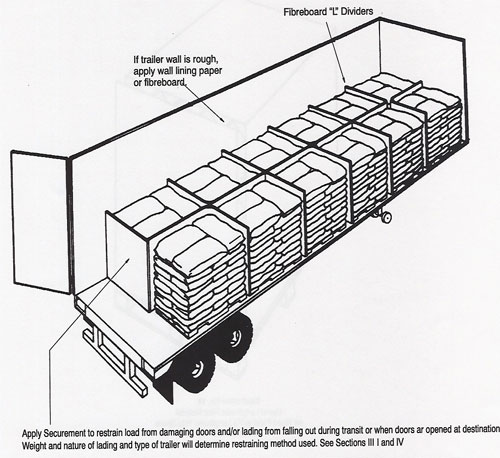

- Cargo must be secured on all sides (especially towards the door) to prevent shifting

- Articles of cargo that are likely to roll must be restrained by chocks, wedges, a cradle or equivalent means

- Articles of cargo beside each other must be placed in direct contact with each other or prevented from shifting towards each other while in transit

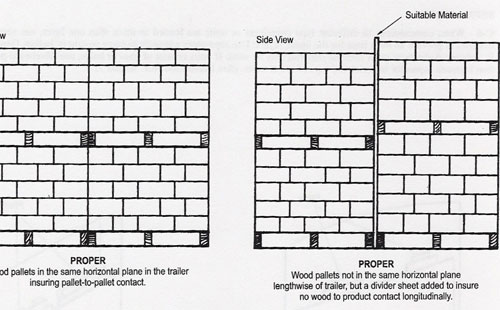

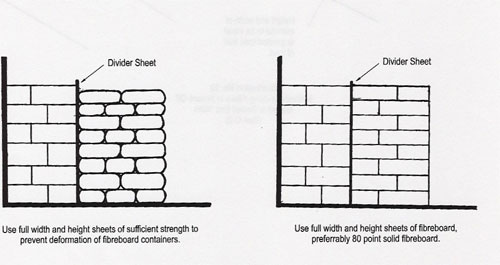

General cargo securing rules(contd)

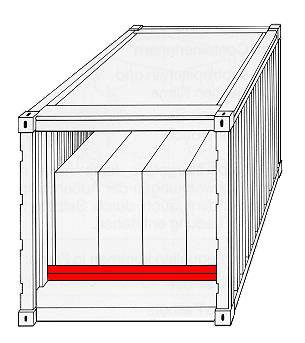

- Spaces between articles of cargo and/or container walls must be filled

- Divider sheets are used when loading pattern is changed or different sized articles of cargo are loaded at adjacent location

- Use the lashing points provided inside the container

- Make full use of the physical attributes of the articles of cargo for blocking, bracing or interlocking

Minimum strength of cargo securing devices and systems

The aggregate working load limit of any securing system used must at least be onehalf times the weight of the cargo

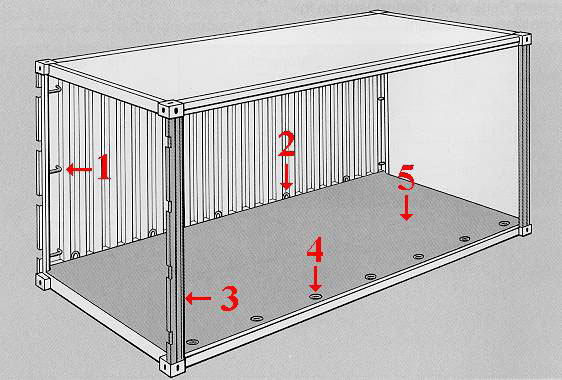

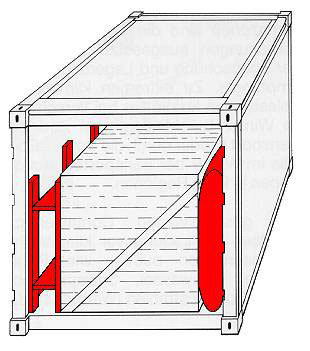

Cargo securing components in the container

How to use the cargo securing components?

| Component | Cargo securing |

| Lashing bars on corner posts,on top and bottom side rails or lashing rings on the floor | For fastening ropes, plastic strapping,steel strapping , rapid tensioners etc. |

| Corrugated steel side walls | Transverse beams may be fitted into the corrugations |

| Corner posts | Shoring |

| Wooden container floor | Anchorage by lumber connectors, nailable |

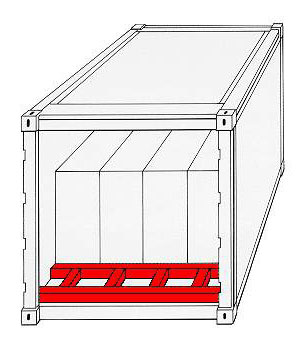

Cargo securing aids 1

Bracing ,blocking and dissipating pressure

- Wooden beams

- Planks

- Squared lumber

- Wooden dunnage

- Boards

- Stowage gratings

- Empty pallets

- Air bags

- Intermediate floors and partitions

Cargo securing aids 1.1

Cargo securing aids 1.2

Cargo securing aids 1.3

Cargo securing aids 1.4

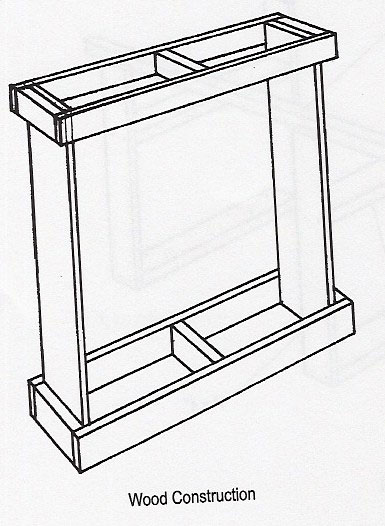

Cargo securing aids 2

Securing cargo in sections:

- Wooden beams

- Planks

- Squared lumber

- Wooden dunnage

- Boards

- Stowage gratings

- Empty pallets

- Air bags

- Intermediate floors and partitions

- Nets

Cargo securing aids 2.1

Cargo securing aids 2.2

Cargo securing aids 2.3

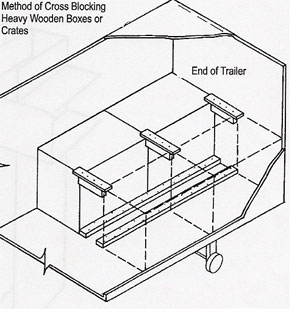

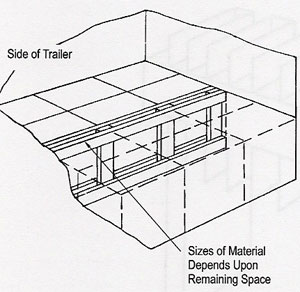

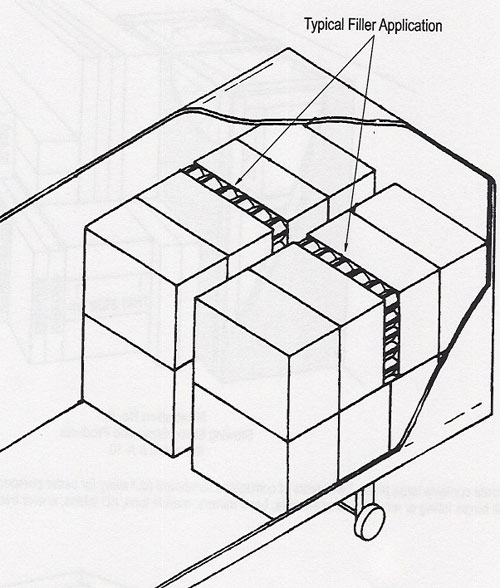

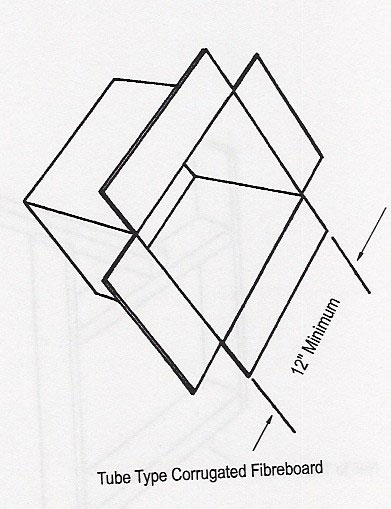

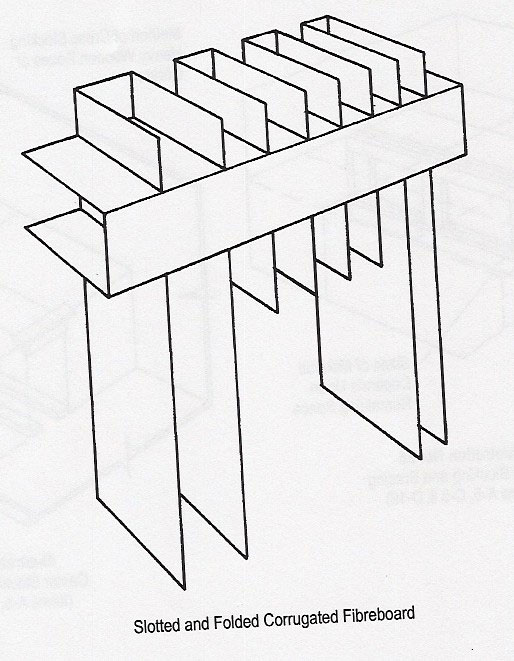

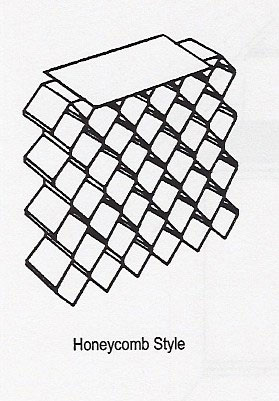

Cargo securing aids 3

Filling dead space

- Wooden beams

- Planks

- Squared lumber

- Wooden dunnage

- Boards

- Empty pallets

- Air bags

- Foam

- Corrugated boards

Cargo securing aids 3.1

Cargo securing aids 3.2

Cargo securing aids 3.3

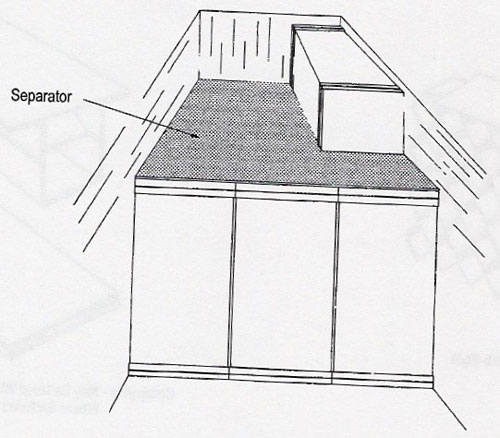

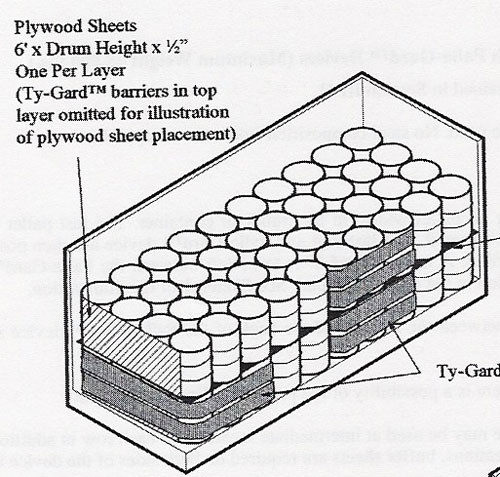

Cargo securing aids 4 Loading in several layers

- Wooden beams

- Planks

- Squared lumber

- Wooden dunnage

- Boards

- Stowage gratings

- Intermediate floors and partitions

Cargo securing aids 4.1

Cargo securing aids 4.2

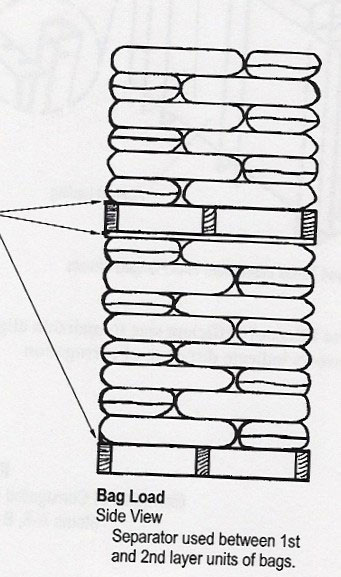

Cargo securing aids 5 Separating different cargoes

- Wooden beams

- Planks

- Squared lumber

- Wooden dunnage

- Boards

- Stowage gratings

- Empty pallets

- Air bags

- Intermediate floors and partitions

Cargo securing aids 5.1

Cargo securing aids 5.2

Cargo securing aids 6

Securing cargo to lashing points

- Nets

- Ropes

- Wire

- Belts

- Steel strapping

- Plastic strapping

- Chains

- Nylon tape

- Hercules

- Rapid tensioners

Cargo securing aids 6.1

Cargo securing aids 6.2

Cargo securing aids 7

Increasing friction

- Plastic mats

- Coconut fiber mats

- Sacks

- Rough paper

- Non-slip spray

- Rubber mats

Cargo securing aids 7.2